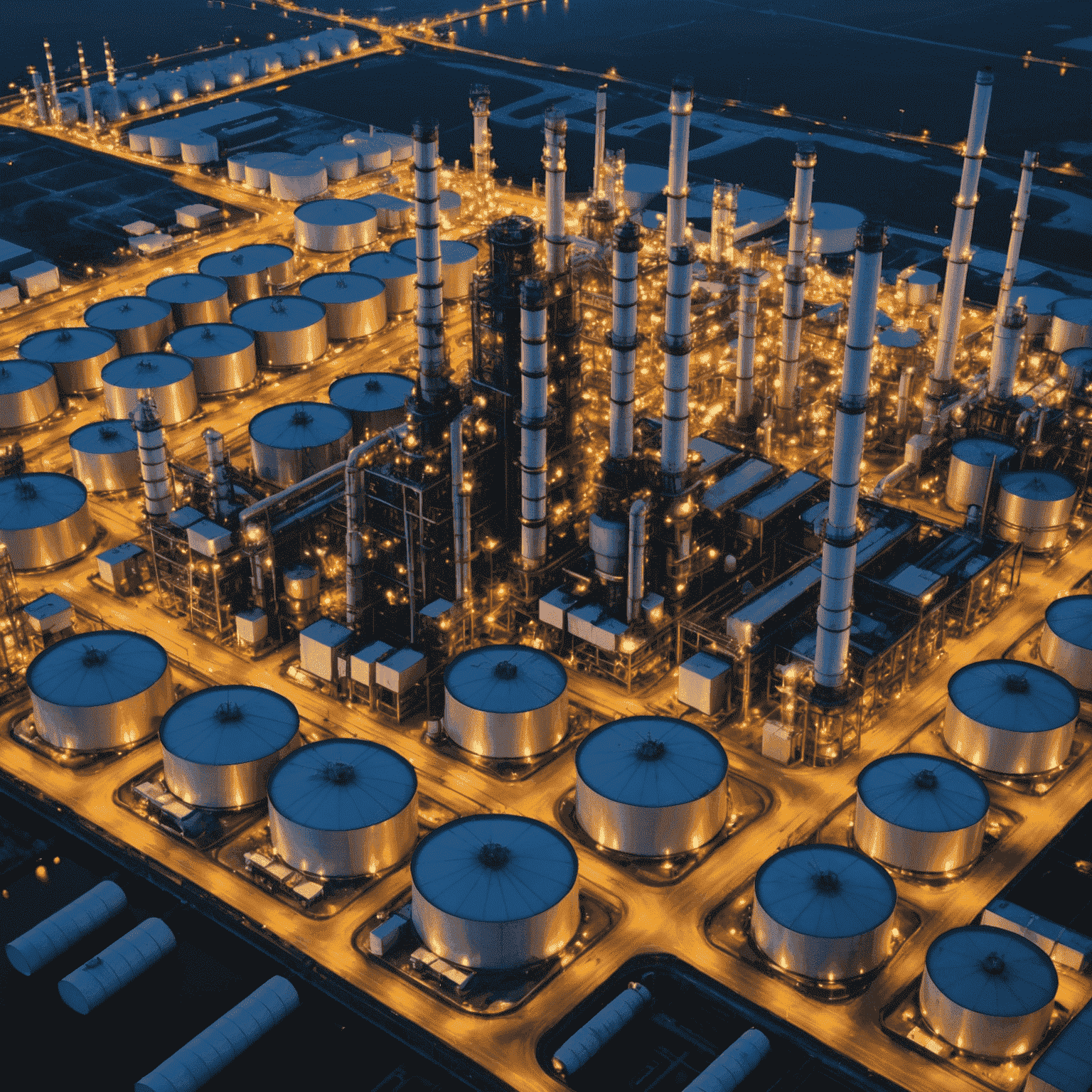

Oil Refining Process Explained

The oil refining process is a crucial step in transforming crude oil into the various petroleum products we use daily. This article will take you through the main stages of oil refining: distillation, cracking, and treating.

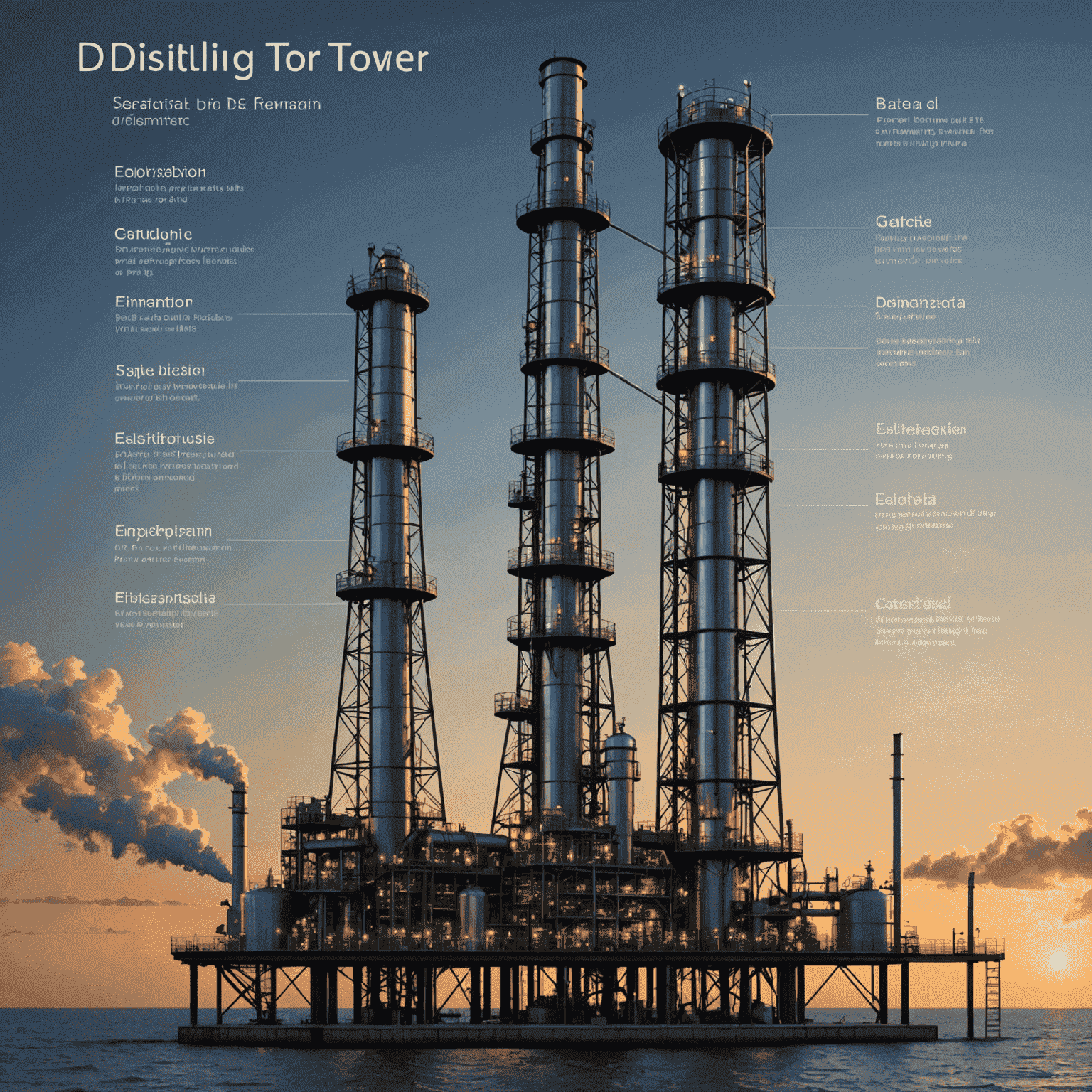

1. Distillation: Separating the Components

The first step in the refining process is distillation, where crude oil is heated and separated into different components based on their boiling points.

- Crude oil is heated to about 350°C in a furnace.

- The heated oil enters a distillation tower where it separates into various fractions.

- Lighter components like gases and gasoline rise to the top.

- Heavier components like diesel and residual oils settle at the bottom.

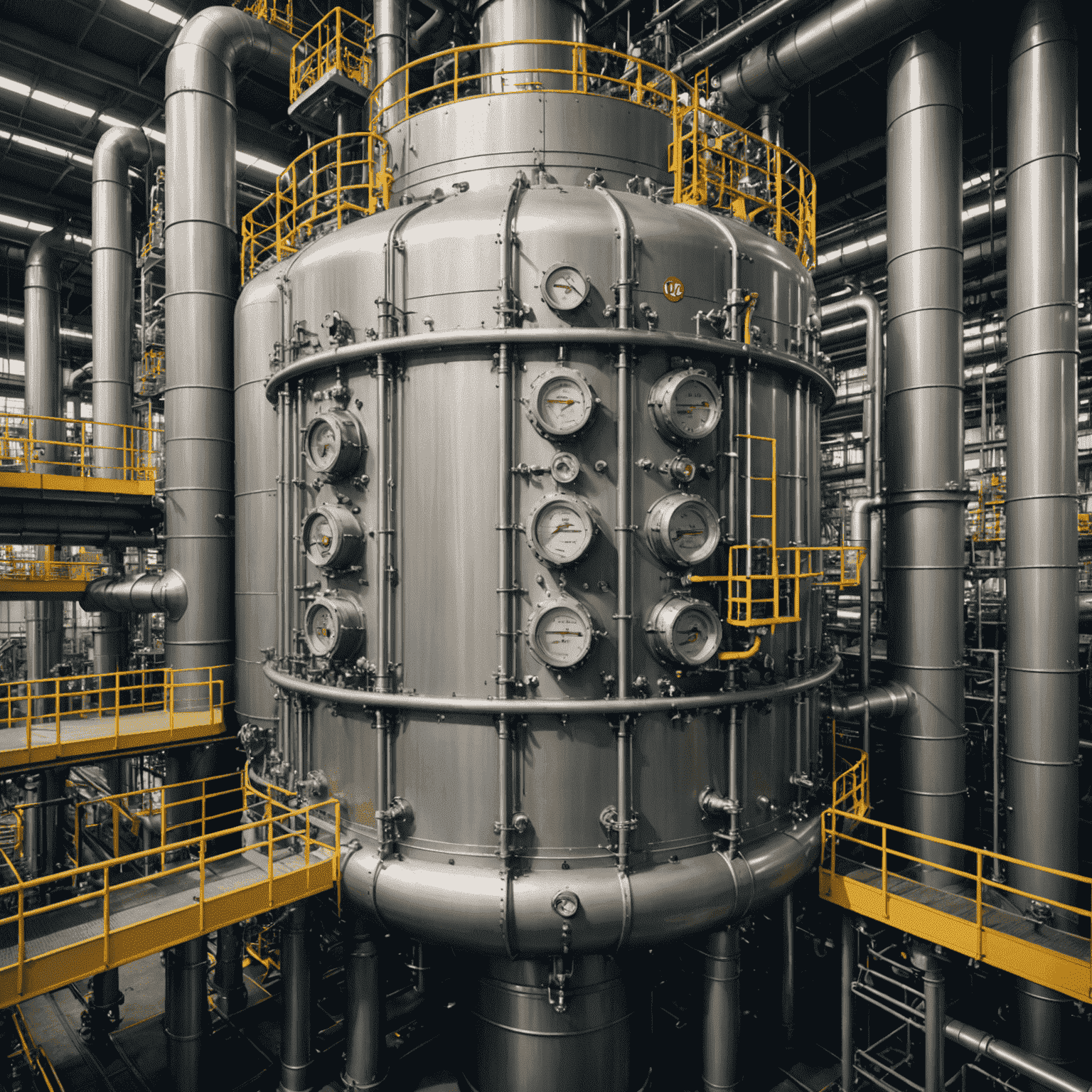

2. Cracking: Breaking Down Heavy Molecules

After distillation, heavier hydrocarbon molecules are broken down into lighter, more valuable products through a process called cracking.

Types of Cracking:

- Thermal Cracking: Uses heat and pressure to break down molecules.

- Catalytic Cracking: Employs catalysts to facilitate the breaking of molecular bonds.

- Hydrocracking: Combines hydrogen with catalysts to break heavy oils into lighter products.

Cracking allows refineries to produce a higher yield of valuable products like gasoline from heavier crude oil components.

3. Treating: Purifying the Products

The final major step in oil refining is treating, which removes impurities and improves the quality of the refined products.

- Hydrotreating: Removes sulfur compounds, improving fuel quality and reducing emissions.

- Sweetening: Converts mercaptans (sulfur compounds) into less harmful disulfides.

- Acid treatment: Removes impurities and improves color and stability of products.

The Importance of Oil Refining

Oil refining is a critical process in the petroleum industry, enabling the production of a wide range of products from a single raw material - crude oil. From the gasoline that powers our vehicles to the asphalt used in road construction, refined petroleum products play a significant role in our daily lives and the global economy.

As the energy landscape evolves, refineries continue to adapt, improving efficiency and developing new techniques to meet changing market demands and environmental regulations. Understanding the refining process is key to appreciating the complexity of oil production and its impact on energy resources worldwide.